Panels, cores, profile bars.

Lightweight: reduction of weight up to 70%

Unsensitive against humidity

Direct screwing without predrilling

Furniture edges directly glueable

- screwable

- outstanding thermal insulation

- economic

- stable in form

- long-term stable

- frost resistant

- isotropic

- ductile

- open to diffusion

- high compressive strength

- low weight

- biocid-free

- recycleable

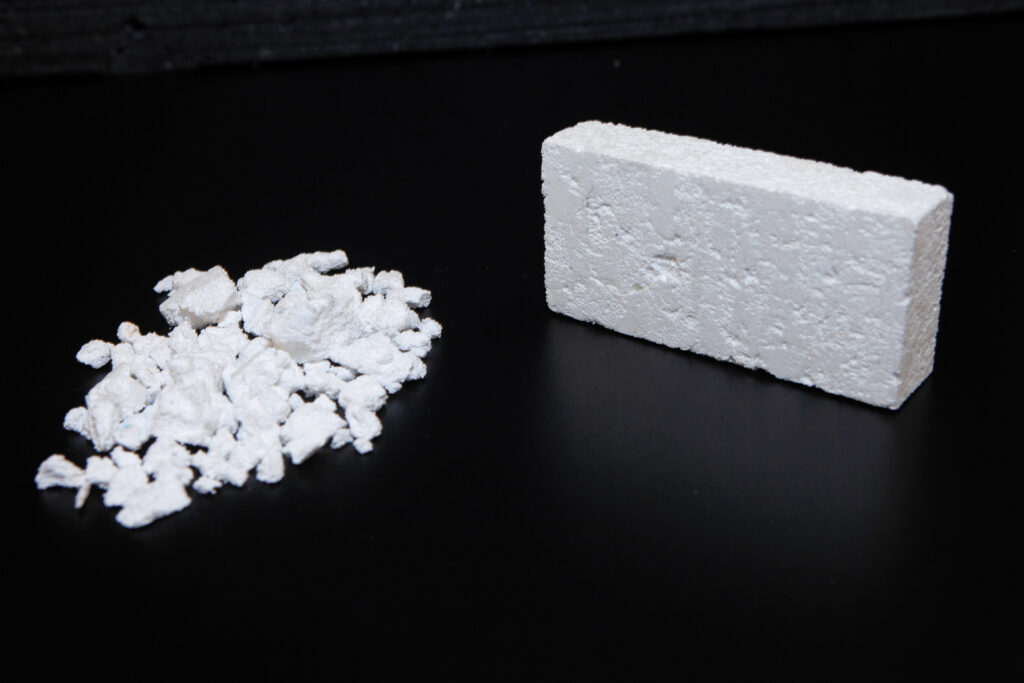

compatto

A modern material.

It combines strength with outstanding thermal insulation and a very low weight. It is both a flexibly usable construction element and a high-grade insulation material. This combination means that COMPACFOAM is extremely versatile.

Our panels, bars, profile bars and blocks goods have a comparatively low weight.

Our panels, bars, profile bars and blocks goods have a comparatively low weight. This makes handling easier. In addition, they can be screwed, drilled, sawed, planed and milled with standard woodworking machines. The ductile property enables the material to compensate for unevenness of the contact surface without any damage. COMPACFOAM is insensitive to moisture and frost, stable up to a temperature of 90°C. It does not become brittle at low temperatures and is therefore also suitable for applications in the field of refrigeration technology. There is no swelling and shrinking and the material is resistant to aging as well as non-rotting.

COMPACFOAM is available as a sandwich panel, core panel, bar or profile bar. Standard formats in all required thicknesses (see table) and custom-made special cuts according to customer requirements are generally possible. We have many options for fabricating the panels to the customer specification.

COMPACFOAM is recycleable, non-mixed and meets all the requirements for sustainable, environmentally friendly construction. COMPACFOAM opens up new approaches to solutions in modern construction as a result of its properties.

compatto

Outstanding properties speak for themselves.

Sandwich

Available as sandwich panel with several surfaces as kraft paper, MDF, laminate and others. Compacfoam compatto can be delivered as sandwich panel core with bespoken thickness and sanded surface with tolerance of +-0,2 mm.

Lightweight

Weights significantly less than standard wood based panels. The extreme lightness combined with the high strength allows weight reduction up to 70% and so a variety of new applications. The high strength of the material allows to apply very thin surfaces.

Furniture edges

Furniture edges can be applied directly to the material with standard methods.

Like wood

Semifinished surfaces like MDF, kraft paper, Plywood enable easy painting and application of veneer with standard methods.

Bending stiffness

The high tensile strength of the surfaces and the rigid core result in a sandwich panel with very high bending stiffness. Because of the excellent dimensional stability of the core the panels remain plain and without torsion even with changing moisture and temperature conditions.

Climate stable

The construction core is insensitive against moisture, temperature and freezing, but still open to diffusion and breathable. That is especially important for the contact with wood. Incoming moisture can dry out damage free. Excellent durability in moist and salty environment. No long term change of material properties.

Screwing

Conventional wood screws are used for screwing. No pre-drilling is required.

Bonding

COMPACFOAM can be easily bonded to other materials with e.g. 1-component polyurethane or MS polymer adhesives.

Economic

No reinforcements of the panel core are necessary at attachment points. The size of the panels adapts to the desired format, which reduces waste costs. Delivery as a fixed size and sanded on both sides possible.

Health

COMPACFOAM is pure and does not release any physiologically relevant amounts of chemical substances. No harmful dusts or vapors are produced during processing.

Heath insulation

Despite its high strength, COMPACFOAM is excellent thermal insulation. Even thin layers prevent thermal bridges and contribute to insulation.

compatto

Applications

Developed from the requirements of modern yacht, vehicle and furniture construction. It combines the advantages of well-known wood-based materials with the lightness and moisture resistance of a unique and revolutionary material that has been successfully used in the construction industry for years.

Applications in the area of yacht construction include: partition walls, furniture parts also made of veneered wood, sanitary components.

In furniture construction: 3D panels, lightweight panels, waterproof outdoor furniture.

In the construction industry: window and door installations, thermal breaks in facades and much more.

compatto

A modern material which consists of pure EPS.

It combines strength with outstanding thermal insulation and a very low weight. It is both a flexibly usable construction element and a high-grade insulation material. This combination means that COMPACFOAM is extremely versatile.

Available also recycled

We can recycle 100 percent of COMPACFOAM waste by means of a newly developed process called particle technology. CF eco, the result of this process, offers the same excellent properties as COMPACFOAM: high strength with outstanding thermal insulation.

Customers can return non-mixed waste to the manufacturer. This makes COMPACFOAM eco an extremely sustainable product. In addition, the customer incurs none of the usual disposal costs.

Research and development